COVID-19 Era - Solutions for Medical Companies to Win the Protracted Battle

9/14/2020 by Marketing Team

EvaluateMedTech™ released a report in 2018 estimating that the global medical device industry achieved a compound growth rate of 4.4% from 2011 to 2018. The total market value in 2018 reached US$440 billion. They forecasted that by 2024, the market size would reach $595 billion with an average annual growth of 5.6%.

In early 2020, the COVID-19 virus was confirmed as a pandemic by World Health Organization (WHO) due to the significant spread around the Globe. While many industries have been impacted tremendously, the medical industry has been brought into the spotlight due to the soaring demand for medical devices.

Considering the phenomenal demand driven by the pandemic, the growth rate is expected to be much higher than the previous estimation.

As a leading hot runner supplier, Mastip is recognized as an “Essential service provider” by the New Zealand government. Leveraging manufacturing capabilities from factories in both China and New Zealand, Mastip continues to provide high-quality hot runner solutions to our global medical customers with minimum disruption during the COVID-19 pandemic.

Mastip supplies hot runner systems to a wide range of critical medical solutions including PPE (personal protective equipment) such as hand sanitizer packaging and face shields, diagnostic products such as nasal and throat swabs, pipettes, blood tubes, and respirator components such as casings, connectors, oxygen masks and humidifiers.

Mastip understands the critical demand on medical products meeting their tight production schedules and ultimately reaching those healthcare services. Mastip has a vast global network ready to support your every need.

With decades of experience supporting medical customers, Mastip provides reliable and cost-effective solutions to ensure our customers maximise their productivity. Here are two examples:

Improved Wear Resistance

During 24/7 high-volume production, hot runners tips can wear out prematurely resulting in several potential issues. For instance, flashing or stringing on the product, visible gate vestige, or excessive cold slug in the gate area eventually blocking melt from filling the cavity.

|

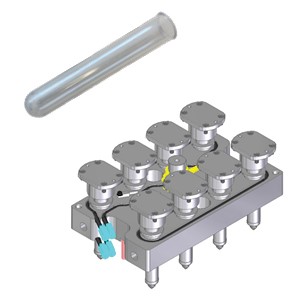

Close pitch solution During COVID-19, the demand for disposable medical devices such as syringes, blood collection tubes and pipettes has increased with the growing number of infections worldwide. Mastip’s multi-gate solutions are engineered specifically for challenging applications requiring close-pitch gates in restricted areas.

|

In response to mitigate those risks, Mastip provides medical customers with long-lasting solutions to extend the tool’s service life. Manufactured from hard wearing tungsten carbide material, the unique G5 tips provide excellent thermal performance. Whether it’s the first shot or the millionth shot, G5 tips ensure consistent gate quality and conformity every time.

Both axial and side gating are available with Mastip’s multi-gate solutions, which optimize the mould layout to achieve cost-effective production. In addition, the service-friendly design allows operators to service the tips without removing the mould from the injection moulding machine once cavity plate is removed.

|

Currently there are more than 31+ million confirmed cases of COVID-19 globally and the virus has spread to more than 200 countries and regions. Although many countries have enforced mandatory lock-down periods to reduce the spread of the virus, it has not disappeared but instead slowly evolved into a "protracted war."

As a trusted hot runner solution provider, Mastip will continue to provide products and services to support our medical customers to win the battle.

Examples of How Mastip Can Solve your Future Closure Needs

|

Application Details Requirements Mastip Solutions |

|

|

Application Details Requirements |

|

|

Application Details Mastip Solutions |

|