Three Common Pain Points With High-Performance Polymers

2/3/2021 by Mastip Marketing

As previously introduced in Part 1, engineering and high-performance polymers present a variety of advantages compared to metals. However, they also pose challenges to the injection moulding process. In this article we explore three common pain points with Engineering Polymers.

1. Reinforced polymers can cause abrasion to hot runner systems.

Modifying polymers with fillers or flame-retardant additives is a common way to achieve better performance while reducing their part weight and cost (compared to metal alternatives). On the other hand, modified polymers can make the injection moulding process challenging due to their abrasive nature.

Take the most popular reinforced filler, glass fibre, as an example. After polymers are reinforced by glass fibres, moulds can wear rapidly as hard and stiff glass fibres rub aggressively against the metal surface. Premature wear not only compromises the part quality but can also significantly shorten the lifetime of the mould.

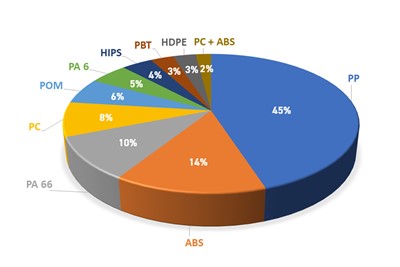

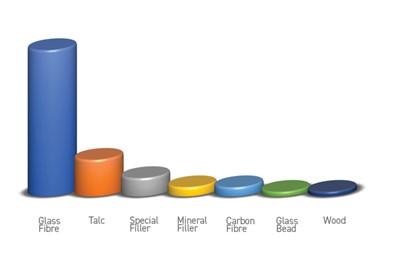

Top 10 Polymer Types from 2010 to 2020 Most Processed Fillers from 2010 to 2020

|

|

Over the last ten years approximately 55% of all Mastip systems are designed and manufactured to process challenging engineering polymers.

MASTIP’s hot runner systems have been specially engineered and manufactured to provide ideal solutions for highly abrasive applications. In the past decade, Mastip has supported customers in a broad range of industries to efficiently process reinforced polymers with up to 65% Glass Fibre.

Benefitting from continuous material innovation, Mastip developed the G5 tip range for the most abrasive polymers. G5 tips incorporate tungsten carbide material with titanium nitride coating, which significantly improves the wear resistance of the hot runner system. The G5 tip is complimented by the H5 nut to guarantee a long-life solution for processing engineering polymers to maintain the gate for millions of shots.

2. Corrosive flame-retardant additives

Flame retardant additives are added to polymers to slow down combustion. They become important in automotive, electronic & electrical industries to improve product safety. However, some of the flame-retardant additives can cause corrosion to the mould. If mould steels are not selected properly, moulds can be corroded very fast, incurring high maintenance and production downtime

Recently, Mastip has expanded MX, BX and SX nozzle series by adding 420 stainless steel (SS) as a standard option. Now stainless steel (SS) can be selected for polymers with corrosive properties.

3. High-temperature polymers processing

High-performance polymers offer the best mechanical strength, chemical and wear resistance among polymer families. These polymers can be processed at more than 150C continuous service temperature due to their rigid polymer chains. However, the moulding process of high-performance polymers is much more challenging than others.

High melt temperature and residence sensitivity of high performance polymers requires hot runner systems to have optimized thermal profiles. This prevents material degradation which can result in mechanical property defects and poor aesthetic quality.

Mastip has accumulated decades of best practice in high process temperature polymers, such as PEEK, PAEK, PEI, PPSU and can confidently offer our customers the most reliable solutions via:

- Optimal design to ensure uniformed thermal profile and reduce material residence time.

- High precision manufacturing to eliminate dead spots for plastics hang-up and degradation.

- Continuous investment in R & D to bring the latest technology into our solutions.

Latest Solutions for High-Temperature Moulding

Fully assembled single valve gate VeriShotᵀᴹ system has been added to Mastip’s high-temperature solution portfolio.

VeriShotᵀᴹ employs patent-pending technology that includes specially engineered high-temperature resistance mechanisms and adjustable valve pins to provide the most robust and service friendly solutions. Compounded multi heaters design, which allows each zone to be precisely optimized, with Mastip’s advanced heating technology, VeriShot can achieve the exceptional thermal performance and make it an ideal solution for demanding engineering polymers.

Examples of How Mastip Can Solve your Future Engineering Polymer Needs

|

Application Details Requirements Mastip Solutions |

|

|

Application Details Mastip Solutions

|

|

|

Application Details Mastip Solutions |

|